Home / All / about products / Do you know the detail information about plastic chain and modular belt?

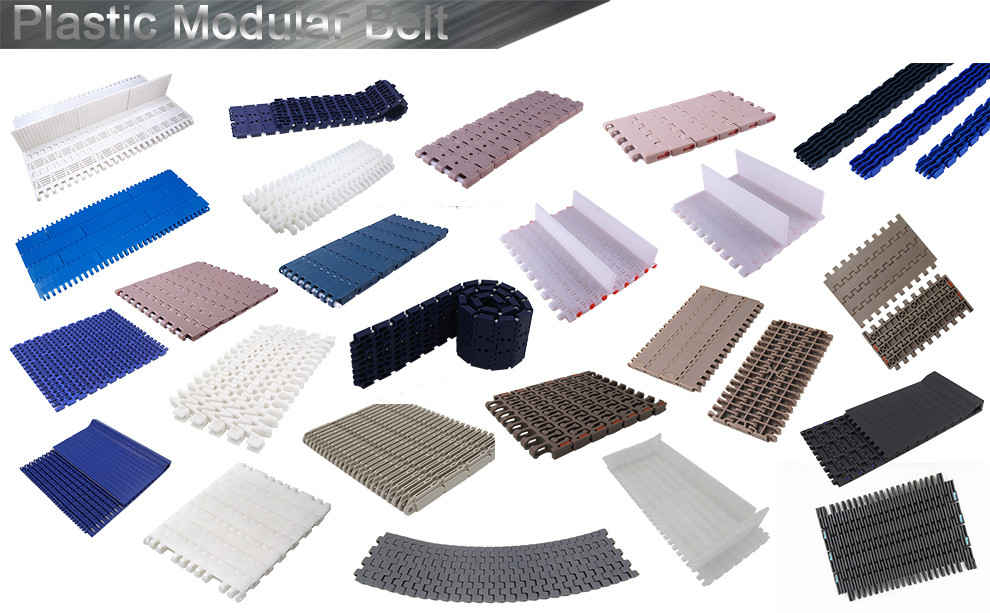

Do you know the detail information about plastic chain and modular belt?

The plastic chain plate and plastic modular belt are a chemical product mainly made of plastic steel ACETAL.

Plastic chain plates, the main materials are: steel ACETAL, polypropylene, PP, polyethylene, PE, nylon, PA, belonging to a conveyor belt, and this is a new type of conveyor belt, has many advantages over traditional conveyor belt: with high Strength, acid, alkali, salt and other characteristics, a wide temperature range, good anti-adhesion, can be added to the baffle, lifting angle, easy to clean, easy maintenance. Can be used for transportation in various environments. Such as the pharmaceutical industry, food industry, packaging industry, daily chemical industry, automotive industry, logistics industry, entertainment facilities, conveyor belts, conveyor equipment.

Transportation and routine maintenance

1. During transportation and storage, the conveyor belt should be kept clean from direct sunlight or rain and snow, and prevented from acid, alkali and oil.

Solvents and other substances are in contact with each other and are located one meter away from the heating device.

2. The storage temperature should be kept between 18-40 °C during storage, and the relative humidity should be kept between 50-80 %.

3. During the storage period, the product shall be placed in a roll and shall not be folded. It shall be turned once every quarter during storage.

4. The conveyor belts of different types and specifications should not be used together, and the joints are preferably glued.

5. The type, structure, specifications and layers of conveyor belts should be selected according to the conditions of use.

6, conveyor belt running speed should generally not be greater than 2. 5 m/s, large block, large abrasive material and use of fixed pear

The unloading device should use low speed as much as possible.

7. The relation between the diameter of the conveyor roller and the conveyor belt layer, the matching of the driving roller and the reversing roller, and the angle of the roller slot

The requirements should be reasonably selected according to the design rules of the transport aircraft.

8. The feeding direction should follow the running direction of the tape. To reduce the impact on the tape when the material falls, the chute should be adopted to reduce the distance of the material.

From; tape receiving section should shorten the idler spacing and the use of buffer idler for leaking, with compliance with the use of a soft and moderate block plate, so as not to

The material plate is too hard to scratch the belt surface. ?

9. Conveyor belts should pay attention to the following matters in use:

1 to avoid the idler being covered by the material, resulting in poor rotation, to prevent leakage of material stuck between the roller and the tape, pay attention to the lubrication of the active part,

However, no oil transport tape;

2 Avoid starting with load;

3 deviation occurred tape, take measures to correct the application;

4 It was found that the local damage of the tape was repaired when the rayon was applied, so as not to enlarge;

classification

According to the material: polypropylene, polyoxymethylene, polyethylene

According to the pitch points: 12.5mm, 15.2mm, 19.05mm, 25.4mm, 31.75mm, 27.2mm, 38.1mm, 50.8mm, 57.15mm

According to the degree of environmental protection: food grade, non-food grade

According to performance points: high temperature type, oil type, wear type, acid and alkali corrosion type

Company Profile

Yi Wu Sikai Trading Company We are a factory specializing in conveyor chains, modular belts, plastic components, and conveyor systems for 27 years. Most of our products have SGS, ISO, and CE certificates. Currently, we provide services to many big and successful companies such as Vinda, Pepsi Cola, COFCO, Pacific Can, Tech-Long and others. They are all satisfied with our products and have long-term cooperation with us. We make molds for plastic table top chains, modular belts sprockets idler wheels and other plastic components. Additionally we have a professional engineering team to design and produce conveyors according to customer requirements. Our main conveyors include spiral conveyors table top chain conveyors modular belt conveyors stainless steel chain conveyors inclined conveyors gripper conveyors etc., covering different industries such as beverages foods tissues textiles tobacco fruits batteries etc.. Our company is located in Guangzhou; you are welcome to visit us anytime.

Company

Categories

- Tel:

+86-15013068448

- Skype:

- 008615013068448

- Address:

- Maotan Village, Changling Road,Huangpu District, Guangzhou

Newsletter

Subscribe To Our Mailing List

subscription

QR code